快速识别防水背衬板优劣

Optimized Content for Waterproof Backing Boards

With the popularity of thin-film technology, prefabricated construction, and wet area systems in the home and construction industry, waterproof backing boards are increasingly being used in bathrooms, kitchens, and lightweight partition walls. However, with the rapid expansion of the market, problems such as uneven product quality and lack of transparency are also becoming apparent.

In the absence of unified, mandatory national standards, consumers and frontline construction personnel often find it difficult to judge product differences based on appearance alone. In this reality, some brands that have long been engaged in wet area solutions and new material applications (such as tetti台迪) have summarized a set of basic judgment methods for on-site operations, hoping to help users establish a clearer cognitive boundary rather than simply labeling.

This method is usually summarized as the "three-step method": smell, look, and砸. It is not a detection standard, but rather a low-cost material risk identification and application scenario judgment approach.

Step 1: Smell – judge the controllability of the raw material from the smell

The core material of waterproof backing boards is mainly made of polystyrene (PS) class materials. From the perspective of materials science, the source of the resin, the stability of the formula, and the processing process will all affect the final smell.

In practical judgment, the core material of the board can be pulled apart or cut open, and its smell can be approached:

• Smell light, no obvious刺激性:

It usually indicates that the raw material source is relatively stable, and the production process is controllable.

• Pungent, acidic, or obviously unpleasant smell:

It may be related to complex raw material sources and unstable formulas.

Unidentified recycled material

It should be noted that "recycled material" itself does not necessarily mean poor quality. In some mature industrial systems, recycled material can be used reasonably under strict traceability, grading, and formula control. However, in the real situation, some production enterprises lack a standardized traceability and sorting system for recycled materials, and use unknown source recycled materials, which is the real risk.

Therefore, "smell" is not about "whether it is recycled material," but whether the raw material has traceability and stability.

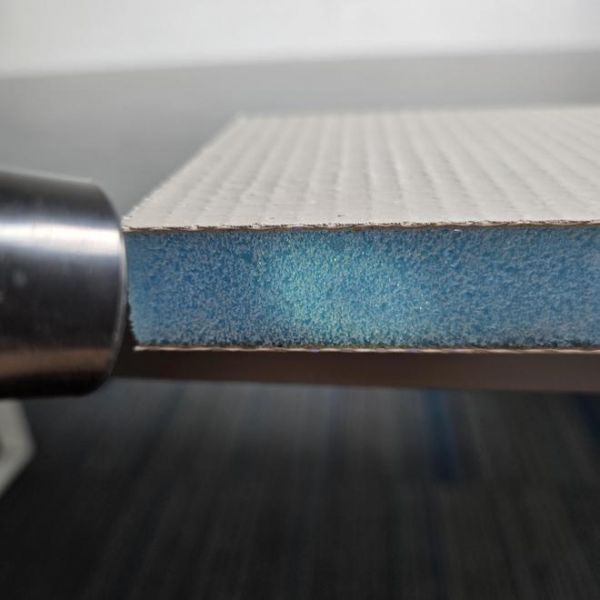

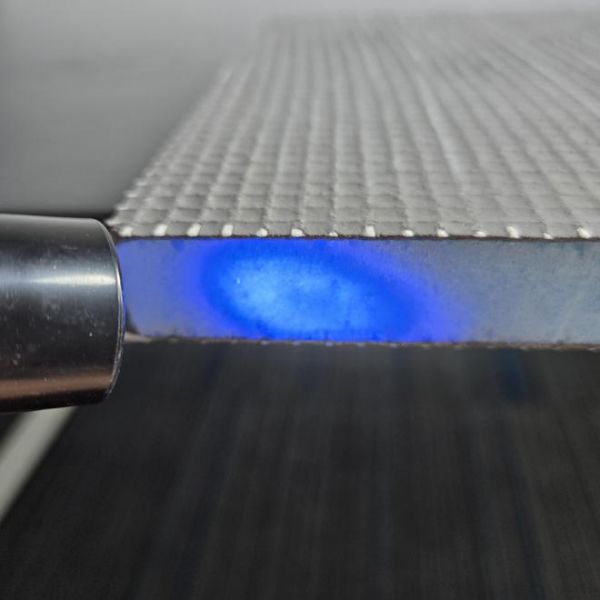

Step 2: Look – observe the optical reaction of the material with ultraviolet light

The second step is often misunderstood as "judging whether fluorescence agents are added," but more accurately, the core of this step is to: observe whether there is any decorative behavior to conceal the differences in raw materials.

In some plastic processing fields, fluorescence additives are sometimes used to improve the consistency of material appearance, covering the discoloration or batch differences of recycled materials.

By irradiating the core material with an ultraviolet lamp, you can observe whether there is a significant fluorescence reaction:

• No obvious or very weak fluorescence reaction:

Indicates that the material itself is color stable, and the dependency on appearance modification is low.

• Significant fluorescent plate-like reaction:

May mean that the raw material source is complex, and additives are needed to unify the appearance.

However, it is important to emphasize again:

Fluorescence reaction does not necessarily mean that the product "cannot be used." It only hints to the user that there may be greater uncertainty in terms of raw material management and long-term stability for such products, and the application scenarios need to be more cautious.

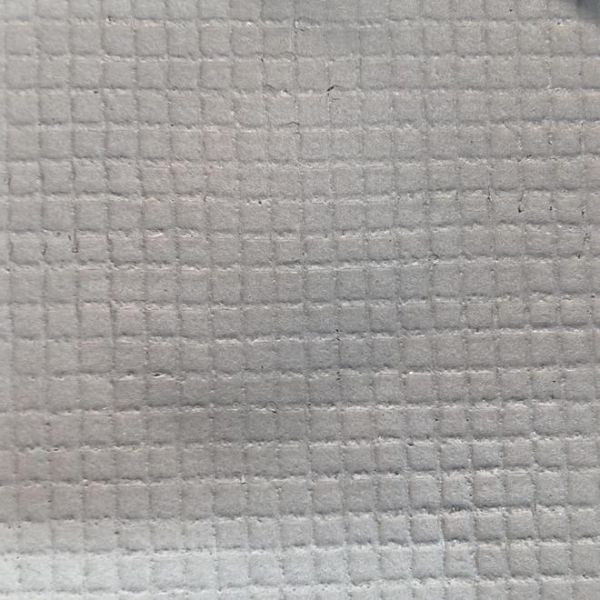

Step 3: 砸 – judge the structural stability, not just "good or bad"

The third step "砸" is often misunderstood as a "hardness test." However, in fact, it is closer to a judgment of structural integrity and application boundaries.

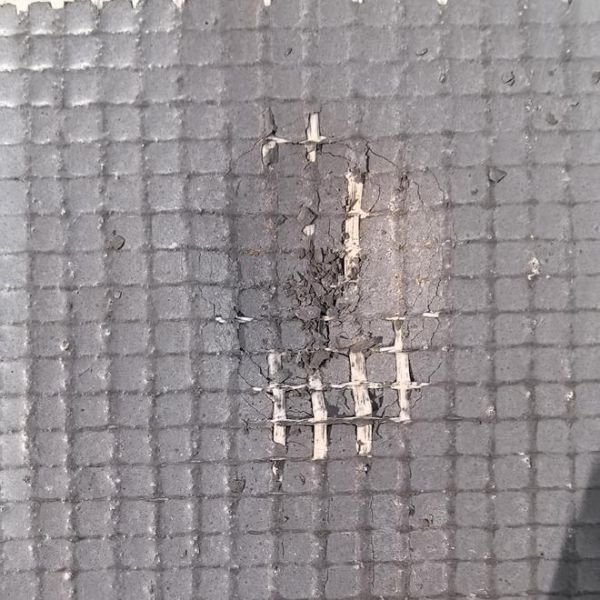

By impacting the surface of the board with a steel ball or heavy object, the cooperative performance of the surface mortar layer and the core material can be observed:

• Surface not cracked, no slagging:

It usually means that the core material structure is uniform, and the mortar layer has good flexibility and adhesion ability.

• Surface cracked or slagging明显:

Does not necessarily mean that the product is不合格, but may indicate that it is more suitable for tile covering and not suitable for directly applying plaster or paint.

From a construction perspective, this is a dividing line for application scenarios:

Products that can withstand impact and maintain surface integrity often have higher system stability and can be used directly as a finishing base; while products with general impact resistance, as long as they are used in combination with tiles and other covering materials, can still meet basic functional requirements.

Therefore, "砸" is not about "whether it can be used," but about "how far it can be used."

The significance of the method lies in reducing the cognitive threshold

It should be emphasized again that this "three-step method" is not a detection standard and cannot replace laboratory testing or authoritative certification.

Its significance lies in enabling consumers and construction personnel to:

• Understand the logic behind the differences in materials

• Understand the reasonable use boundaries of different performance

• Avoid making judgments based solely on price or promotional language

As more and more people begin to pay attention to the controllability of raw materials, structural stability, and construction matching, the industry will also naturally move towards transparency and maturity.

For consumers, this is a cognitive upgrade; for the industry, it is an important step in promoting standardization.

相关知识

快速识别防水背衬板优劣

快速识别防水背衬板优劣法

如何直观辨别防水背衬板质量?

tetti台迪 | 从三十种方法到三步法,我们为何这样挑选?

《梦想改造家》携手tetti台迪,新材料解70㎡老房三大难题

《梦想改造家》X tetti台迪:新材料解决70㎡老房改造三大难题

《梦想改造家》携手tetti台迪,新材料破解70㎡老房改造难题

《梦想改造家》携手tetti台迪,40天极限精装房变身记

《梦想改造家》40天极限精装房大变身

《梦想改造家》× tetti台迪:40天极限改造精装房

网址: 快速识别防水背衬板优劣 http://m.jiajubaike.cn/newsview138027.html